Die Casting Aluminum Alloy Housing Luminaire Lamp Parts LED Casing

Cover Shade

Products Description

1, Aluminium die casting parts are a process of injection aluminium

or aluminium alloy under pressure, which produces parts in high

volume at low costs.

2, There are two processes of Aluminum die casting: hot chamber and

cold chamber.

3, A complete cycle can vary from one second for small components

to minutes for a casting of large part, making aluminium die

casting the fastest technique available for producing precise

aluminium & aluminum alloy parts.

4, Any aluminium die casting parts are customized according to the

clients' drawing or samples.

| Product Name | Die Casting Aluminum Alloy Housing Luminaire Lamp Parts LED Casing

Cover Shade |

| Material Detail | ADC12,A380,ALsi9cu3,ADC10,A356,etc. |

| Tolerance Standard | ISO 8062-3:2007 |

| Other Material | Brass, Iron, Stainless Steel |

| Technology | Die Casting, CNC Machining |

| Application | Luminaire Lamp Parts LED Casing |

Application

Aluminum die castings are widely used in various industries such as

automobile manufacturing, internal combustion engine production,

motorcycle manufacturing, electric motor manufacturing,

transmission machinery manufacturing, precision instruments, garden

beautification, electric power construction, etc.

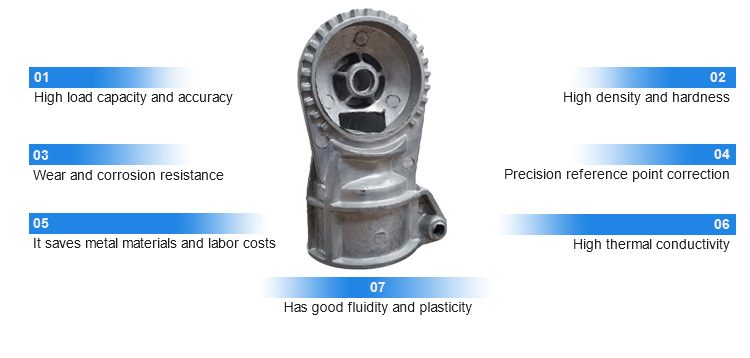

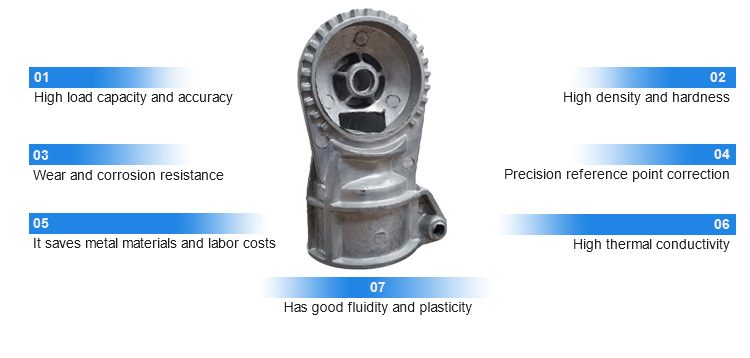

Advantage

1, The aluminum have good fluidity and plasticity, and the casting

process is cast in a pressure die casting machine, the aluminum die

casting can make various complicated shapes, and can also achieve

higher accuracy and accuracy.

2, Aluminum die-casting is also a process with very high resource

utilization, saving a certain amount of manpower and material

resources.

3, aluminum have excellent thermal conductivity , Smaller weight

and higher machinability.

Process

1, Sign Drawing (General clients provide the drawing or samples)

2, Opening the Mould

3, Die Casting ( Aluminium or Aluminium Alloys)

4, Precision Machining (Burring, Lathe, Milling, etc)

5, Surface treatment: Polishing, Electroplating, Sandblasting,

Anodizing

Competitive Advantages

1. We provide products with good quality at best price for clients

in quick delivery.

2. 100% custom pass guaranteed.

3. Always immediate and best after-sale service.

4. Flexible and negotiable payment terms.

5. Our clients distribute widely, like in UK, France, Germany,

Norway, Poland, Finland, Spain, Russia,USA, Canada, Brazil, Mexico,

Australia, Japan, Thailand, Indonesia, Uruguay and many other

countries.

Packaging

Inside Packing: 1 Pieces per Vacuum Plastic bubble paper.

External Packing: 500-1000 Pieces per Hard Carton

Shipment Packing: 10-20 Cartons per Wooden Case or Pallet

Shipping Term: By Air, Land, Sea.

Trade Term: FOB, CFR, CIF, EXW

FAQ

Q: Are you trading company or manufacturer?

A: We are a factory main produce aluminum die casting, zinc die

casting, cnc parts and tooling molds.

Q: How long is your delivery time?

A: Mold lead time: Within 30 days upon we receive the 50% of mold

charges.

Batch production lead time: With 15 days upon we receive the 30%

deposit.

Q: Can you make the parts based on the samples?

A: Yes, we could make measurement based on your samples and make

the tooling die.