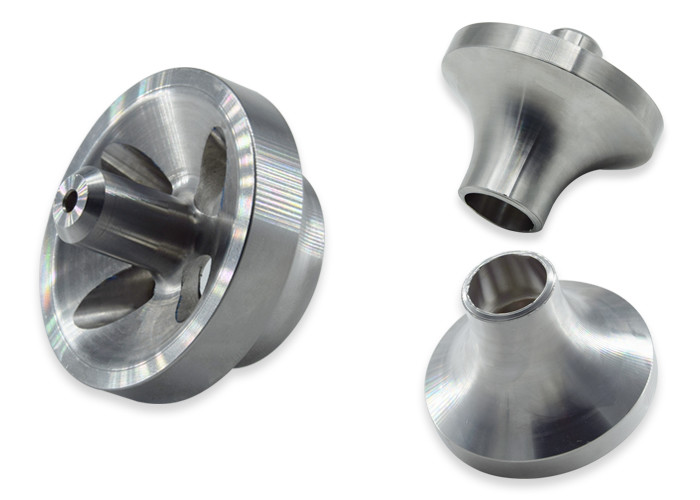

Professional Customized metal Made Precision Machining cnc parts

Description

CNC machining uses stainless steel as raw material. Through the

accurate calculation of advanced CNC processing equipment system,

CNC custom-made products can be accurate to micro-millimeter units.

The company has advanced CNC processing equipment and can produce

non-standard precision parts according to customers' requirements.

NC processing, various aluminum alloys, and other metal products

processing. We are audited by SGS and passed the ISO9001:2008 certification,

specializing in developing and producing high precision CNC

machining parts, milling parts, turning parts according to

customers’ requirements.

In particular, the company has a professional technical production

team and advanced production and processing equipment in the

processing of CNC die castings and stainless steel parts. It

promises to deliver high-precision, high-quality products on time.

Process

Raw material processing - cutting - machining - milling surface

burr processing - surface treatment - product assembly - product

inspection - product packaging.

Machining products require drawings or samples, and it is better to

provide 3D drawings. Please mark the tolerance range or provide the

tolerance standard. You can also inform the accessory parts in

advance. In case of product quality problems, please contact us and

provide photos and test reports. We will return or negotiate with

the customer.

Advantages

1, Processing Equipment:

3 axis / 4 axis / 5 axis CNC machining center, CNC car, walking

machine available; also has a milling center for large parts;

precision grinding machine, EDM, wire cutting and other auxiliary

processing equipment.

2, Precision and size:

The positioning tolerance of milling can be up to ±0.01mm, the

tolerance of machining can reach up to ±0.005mm; the maximum

machining size of milling can reach 2000mm x 1500mm x 800mm, and

the maximum machining can directly reach 400mm.

3, Materials and aftertreatment:

Supports the processing of metals (such as aluminum alloys,

stainless steel, carbon steel, alloys, copper, etc.) and non-metals

(ABS, Teflon PTFE, PEEK, PC, Saigang POM, etc.). It also provides

various post-treatment services such as sandblasting oxidation,

electroplating, silk screen printing and laser.

4, Quantity and processing cycle:

Provide fast proofing, small batch trial production and mass

production services; provide samples in the fastest 7 days, 95%

on-time delivery rate in small batches and batch production in

nearly 30 days; mass production products have good consistency and

competitive prices.

5,Inspection tooling:

We have sophisticated testing equipment to conduct flow inspection

of products in the production process.

The testing equipment includes tool microscope/ digimatic

micrometer/ inside micrometer/ dialgage/ electronic digital display

caliper/ automatic height gauge/ precision level 2 detector/ ring

gauge/ etc.

Our Service

1. Finding the right suppliers well suited your requests ( not only

cheaper).

2. Providing DEWIN DOLPHIN REPORT with the real information about

the suppliers to help you see the unseen and make the correct

decision.

3. Making sure the process of production is according to TS 16949

or our common agreement .

4. Providing financial support to our VIP partners to help them

getting the big project from their clients .

Packaging

Inner Packing: 50 Pieces per Anti-rust plastic film, Vacuum Plastic Bags.

Outer Packing: 500-1000 Pieces per Hard Carton, Wooden Case, Wooden Pallet.

Shipment Packing: 10 Carton per Wooden Case or Pallet

Shipping Term: By Sea, By Express, By Air, By Land.

Delivery Time: General 20-30 Work Days, (Depends on the Amount)

Trade Term: FOB, CFR, CIF.